A New Model for Shipping Container Housing in Ontario. In the quiet town of Burk’s Falls, Ontario, a forward-thinking housing initiative has taken shape. Developer InvestorCentric Inc. is transforming recycled shipping containers into functional, code-compliant residences. The project aims to demonstrate how steel containers can deliver affordable housing while addressing the rental shortage in rural communities. As a standout example of shipping container housing in Ontario, this development merges cost-efficiency, durability, and sustainability.

Phase 1: Overcoming Design and Construction Challenges

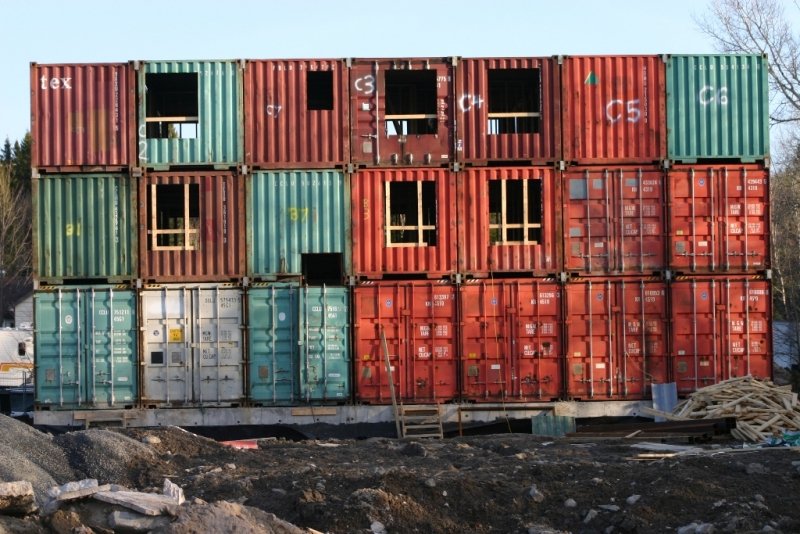

Phase 1 of the Burk’s Falls shipping container housing project began in January 2011. It features a three-storey building with 12 residential units. To begin construction, crews demolished a long-abandoned hotel. The site provided a low-cost location with access to existing infrastructure.

InvestorCentric sourced heavy-gauge steel containers from multiple suppliers. However, construction crews quickly realized that adapting the containers required more than simple modifications. Cutting through the thick structural beams for doors and windows proved difficult, especially in sub-zero temperatures. Plasma cutters failed in the cold, forcing teams to use grinders and torches.

Furthermore, the original building plans followed conventional wood-frame design logic. This oversight led to inefficient workflows. According to company president Teresa Oliver, aligning doorways with the containers’ existing barn-style openings would have simplified the process. Similarly, placing windows away from key structural elements would have preserved integrity and reduced cutting time.

Strength, Speed, and Structural Innovation

Despite early setbacks, the project confirmed the impressive strength and adaptability of steel containers. Their structural integrity exceeds that of wood framing by a factor of 50. Fire resistance, durability, and the potential to stack containers up to 10 storeys make them ideal for modular housing in Ontario.

Instead of welding the units together, crews used the containers’ built-in locking mechanisms, originally designed for ocean freight. These connections proved stronger and more reliable than custom welds.

Trades installed plumbing, HVAC, and electrical systems by cutting small access points into each container. Interior finishes included standard drywall, flooring, and fixtures. Exteriors were completed with traditional roofing and siding. To meet insulation needs, the team applied spray-on insulation across the structure’s outer surfaces.

Affordable Shipping Container Housing in Ontario: Costs and Outcomes

When completed, the apartments offered low rental rates. Bachelor units leased for $625 CAD per month, and two-bedroom units for $825 CAD. These rates positioned the project as one of the more affordable container homes in Canada, especially within rural Ontario.

Landscaping and finishing touches followed in spring. Phase 1 stood as proof that well-executed shipping container housing could provide comfortable, accessible, and affordable living.

Phase 2: Lessons Learned and New Materials

For Phase 2, InvestorCentric maintained the original building footprint but transitioned to wood-frame construction. The decision stemmed from limitations in the Phase 1 design, which did not fully embrace container-specific planning. This pivot allowed for faster implementation, while Phase 3 returned to steel construction with better-informed design choices.

Phase 3: Mixed-Use and Modular Innovation

Phase 3 includes several upgrades over earlier stages. The ground floor now incorporates retail space, occupying approximately 20% of the total footprint. Higher R-value stucco spray insulation improves thermal performance, and a revised layout avoids cutting through structural beams.

While earlier phases used poured concrete foundations, the developer sees future units built more cost-effectively on slab-on-grade bases. With refined processes, InvestorCentric estimates a full three-storey container building could be erected in as little as 11 days.

Future Vision: Modular Housing Ontario and Beyond

Looking ahead, InvestorCentric plans to expand its modular housing Ontario portfolio. The company intends to manufacture pre-fabricated container systems prepared for installation. These units would arrive with utilities pre-cut, framed, and fitted for electrical, plumbing, and HVAC.

This approach positions the company at the forefront of affordable container homes in Canada. Their Burk’s Falls shipping container housing pilot now serves as a blueprint for municipalities, developers, and communities exploring scalable, sustainable housing solutions.

By adapting military-grade design logic and sustainable construction methods, the project not only addressed housing shortages—it redefined what modern modular housing can look like in rural Ontario.

Courtesy Of: dcnonl.com

Join the conversation on sustainable living — comment by