Note: On some ISO shelters, some of the primary structural components may be concealed within the wall, roof, and floor panels. The areas where the adjacent panels join will be thoroughly inspected. This inspection will meet the criteria for the Wall Beams and the Roof Beams

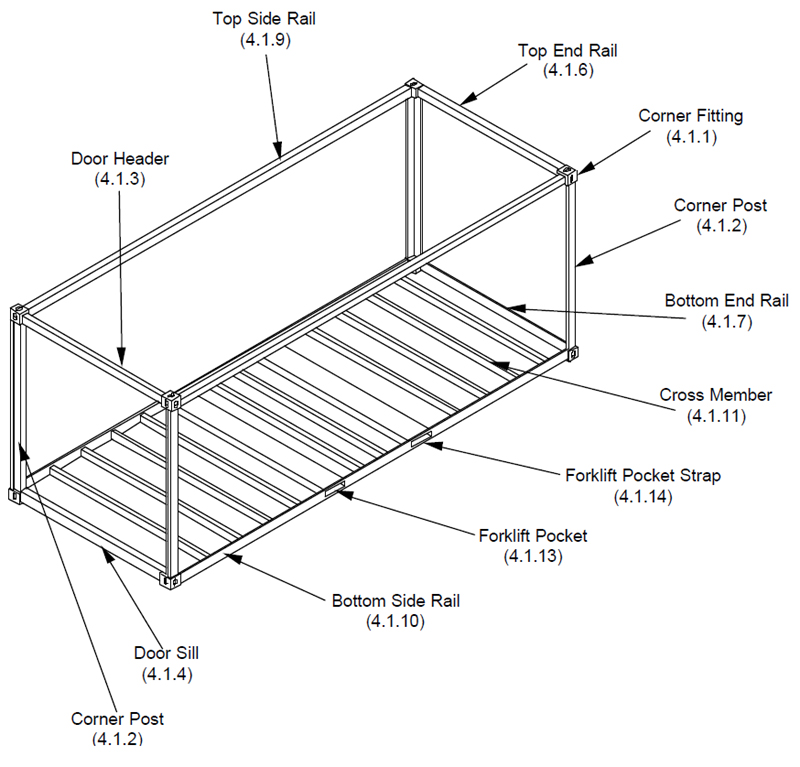

4.1.1 Corner Fitting. Internationally standard fitting (casting) located at the eight corners of the container structure to provide means of handling, stacking and securing containers. Specifications are defined in ISO 1161.

4.1.2 Corner Post. Vertical structural member located at the four corners of the container and to which the corner fittings are joined.

4.1.3 Door Header. Lateral structural member situated over the door opening and joined to the corner fittings in the door end frame.

4.1.4 Door Sill. Lateral structural member at the bottom of the door opening and joined to the corner fittings in the door end frame.

4.1.5 Rear End Frame. The structural assembly at the rear (door end) of the container consisting of the door sill and header joined at the rear corner fittings to the rear corner posts to form the door opening.

4.1.6 Top End Rail. Lateral structural member situated at the top edge of the front end (opposite the door end) of the container and joined to the corner fittings.

4.1.7 Bottom End Rail. Lateral structural member situated at the bottom edge of the front end (opposite the door end) of the container and joined to the corner fittings.

4.1.8 Front End Frame. The structural assembly at the front end (opposite the door end) of the container consisting of top and bottom end rails joined at the front corner fittings to the front corner posts.

4.1.9 Top Side Rail. Longitudinal structural member situated at the top edge of each side of the container and joined to the corner fittings of the end frames.

4.1.10 Bottom Side Rail. Longitudinal structural member situated at the bottom edge of each side of the container and joined to the corner fittings to form a part of the understructure.

4.1.11 Cross Member. Lateral structural member attached to the bottom side rails that supports the

flooring.

4.1.12 Understructure. An assembly consisting of bottom side and end rails, door sill (when applicable), cross members and forklift pockets.

4.1.13 Forklift Pocket. Reinforced tunnel (installed in pairs) situated transversely across the understructure and providing openings in the bottom side rails at ISO prescribed positions to enable either empty capacity or empty and loaded capacity container handling by forklift equipment.

4.1.14 Forklift Pocket Strap. The plate welded to the bottom of each forklift pocket opening or part of bottom siderail. The forklift pocket strap is a component of the forklift pocket.

4.1.15 Gooseneck Tunnel. Recessed area in the forward portion of the understructure to accommodate transport by a gooseneck chassis. This feature is more common in forty foot and longer containers.